Parameters Made Easy – Well Hopefully

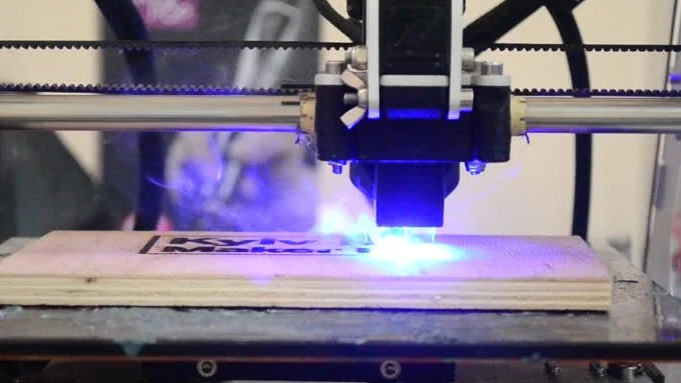

When I started in the laser industry very few of us knew the limits of laser cutting and engraving. We tested every new laser that came to market and pushed those limits. Nothing has changed in the past 40 years. When we get our new laser, we still want good cutting or engraving parameters. Experience is something hard to replace but there are good parameter tables out there to help you get a starting point.

When you search the internet, you’ll find hundreds of places posting laser settings for a wide variety of materials and laser systems. They are often conflicting, nothing like you’re seeing, hard to understand, and don’t match your lasers parameter formats – or they just seem that way!

To get the best parameters for your laser you need to understand the basic laser machine functions and technologies. I’m not saying you need to work for NASA, but just understand how the machine works will help you develop laser parameters for your products.

Lasers use settings like Speed and Power to engrave and cut. They are easy to understand numbers and are based on basic machine movement and power abilities. These are the two most basic settings, you will also see things such as Focus, DPI or LPI, Min and Max Powers, Number of Passes or direction or engraving. All these can be daunting when combined. I hope to add some simplicity and clarity to the parameters so you can begin to explore and develop new techniques and products with your laser!

Let’s look at some of the basic parameters:

SPEED

Speed is simply how fast the laser nozzle is moving across the work area. It’s often recorded in millimeters per second (mm/sec). The machine design, laser type, and laser power determine the basic speed setting.

POWER

Lasers produce light of a very specific type (wavelength). This light can be measured for the heat or energy it contains. This is typically called the laser Power often given in a unit of power called Watts. Laser power is directly dependent on the type of laser and how it is made. More on this in my next post.

FOCUS

According to the dictionary Focus is “the center of activity”. Lenses are used to “focus” the laser light to a center of activity or what is called the Focal Point. This Focal Point is used to engrave or cut materials. The basic concept of focus has the laser light entering a lens and through a process of bending the light called refraction it is bent to a very small point of light. This Focal Point may be less than 0.2mm (0.008 inch) in diameter, this is called the Spot Size. The focus is a distance. It is related to the focal length of the lens such as 63.5mm or 2.5inch. However, the term Focus used in parameter settings refers to where that Focal Point is in reference to the surface of the material.

A Focus of 0.1 inches tells you that the Focal Point should be 0.1 inches above the material. A negative Focus setting would have the Focal Point lowered into the material.

The various brands of software and laser systems on the market refer to this differently. Some use the term “Focus Height”, or “Focus” while others use “Z-Offset”. All are trying to achieve the same result – setting the location of the Focal Point in reference to the materials surface.

MIN AND MAX POWERS

Most modern laser control software use settings to define the Minimum (Min) and Maximum (Max) Power used during the laser process. The laser will begin and end the process at the Minimum Power setting and use the Maximum Power setting while cutting or engraving at full speed. When the laser starts to move it will use the Min Power setting as the lowest power it will output. As it accelerates to full speed it will ramp up to the Max Power setting once it achieves full speed. It will also do the reverse – the laser will lower power to the Min Power setting as it decelerates to a corner or end of a cut. This process helps eliminate burnt corners and allows for better detail.

DPI or LPI

Resolution is how many engraved lines can you have per inch or millimeter. Resolution is described in Dot Per Inch (DPI) or Line Per Inch (DPI). Resolution is a basic component of image quality. Higher resolutions in general create better images. High end printers or publishers may require a resolution of 600 DPI for printing, but web site developers may only require 72 DPI. Laser engraving resolution is directly dependent on Focal Point Spot Size. A Spot Size of 0.008 inch will be a resolution of 125 DPI, so a DPI setting of 150 would allow for the Spot Size to overlap and create a smooth image.

DIRECTION

Direction of engraving is what direction do you want the laser to engrave. Direction of engraving is often along the Axis of the laser machine. In various laser control software, you may see something like X-Axis (Left to Right) or Y-Axis (Front to Back) or a defined Scan Angle in degrees. This Direction setting is used to help reduce visible laser engraved lines in your materials. The grains of wood may require a slightly different direction of engraving to achieve the best image quality.

Making two passes over the same image can create a more uniform look and feel. Using a different direction for each pass can make the image darker and more uniform.

Something to remember: The X-Axis is usually the left to right direction on the laser machine. The motors used to move this portion of the laser does not have to work as hard as the Y-axis motor because the laser nozzle and mirror are lighter than the entire gantry that the Y-Axis motor must move. Lighter means you can engrave faster with accuracy so must people engrave left to right or at 0 degrees.

NUMBER OF PASSES

You can engrave a job with one pass and be done. Or you can use multiple passes to achieve your desired result. Engraving with multiple passes increases the time the laser beam is “burning” the material. Making the engraving deeper, darker, or smoother. It’s a technique that you need to experiment with based on your material and desired result.

WHERE TO BEGIN

These are some basic parameters. We can get more in-depth with things like Dwell, Frequency, Duty Cycle, Gas Pressure, Nozzle Diameter, and Nozzle Height. The complexity grows quickly for more advanced machines. But lets focus on the KISS principle.

In general, follow these guidelines:

- Power – Helps determine how fast you can engrave or cut. Also sets the limits on how thick you can cut. Start with lower to mid powers and slow speeds. Slowly and work your way to higher power and speeds.

- Speed – Directly Dependent on Power and Material you are processing.

- Focus – Set focus at surface of material.

- Min Power – Set this low to begin and adjust up if laser is not cutting at start. Adjust down if you see burnt corners.

- Max Power – Usually adjust to match your Speed and Material.

- DPI/LPI – Start with 72, 150, 200, 300, and 600. Adjust up to get more detail and lower to decrease production time but not low enough to decrease quality of engraving.

- Direction – Allow the X-Axis to do most of the work as it’s usually less mass and the machine can move faster with accuracy in that axis.

- Number of Passes – Use on occasion to smooth an engraving or make it darker.

A good setup procedure would look like this:

ENGRAVING

- Start with Focus on surface of material.

- Adjust Power up and/or Speed down for darker engravings.

- Adjust Power down and/or Speed up for easy to engrave materials.

- Adjust DPI up for more detail or to make engraving darker

CUTTING

- Start with Focus on surface of material.

- Adjust Power up and/or Speed down for thicker materials.

- Adjust Power down and/or Speed up for thinner or easy to cut materials.

- Adjust Air Pressure higher if possible, for better performance.

- Adjust Focus down into material as first Focus option.

- Adjust Focus out or above the material as the last Focus option.

I hope this helps. It should at least help your insomnia!

After 40 years of lasering everything from tumblers to M1 Abram tanks, I still have to tweak parameters to get the results I like. So don’t fret, laser cutting and engraving isn’t an exact science – but it’s getting better. Today’s high-end industrial lasers use artificial intelligence to adjust parameters on the fly to get the best cut possible. Maybe some of that AI stuff will find its way into the lower powered laser engraver market. Until then I’ll be adjusting parameters and tweaking setups!

Writer Anthony Isaac can be reached via the Contact Me page.