When I first wanted to start a laser business all I could think of was the cool things that I could cut and sell. I sat down and wrote a business plan on a couple of sheets of paper and was ready to start my business. Well basically, I outlined all the products I was going to make and how I’d sell them. Then it hit me I needed to decide on what laser I was going to use to create all this cool stuff and where to put it!

Like you, I was very excited about my new venture and was ready to just jump right into the business. However, I did take a few months to think things through and list everything I thought I would need to get started. Time was on my side. I had a full-time job working for one of the largest manufacturers of laser cutting systems in the country. This presented the time and opportunity for me to ask questions and learn from hundreds of business owners over the next few months. You see I had worked for this company for 10 years and enjoyed my work – but I knew I wanted to own my own laser business. Now I was planning on starting this business!

Setting My Objective

Why did I want to start this business? I sat down and created a simple list of why I wanted to start this business. It was fun and helped me understand where I wanted to take this business. I kept it simple and focused and set an objective of what the business was going to provide or sell.

This is where we all start in one way or another. I had to decide on what I was selling, what laser I needed, and what software I needed to create the stuff? Well, I broke it down into a few simple steps:

- What laser?

- What essential equipment and software?

Which Laser to Choose?

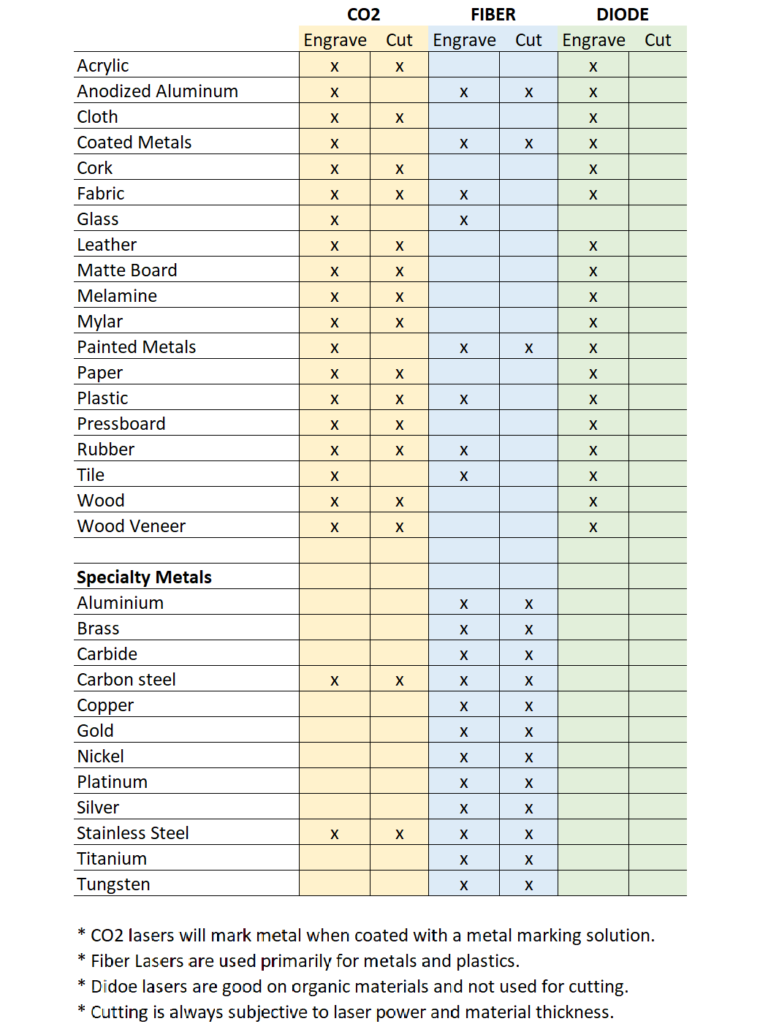

To choose your laser you must first look at the laser source, the part that makes the laser beam. There are a few choices here and you make this choice based upon the material you’ll be engraving and cutting. Here’s a simple breakdown:

- Fiber Laser: This is a laser type that creates the laser beam within a fiber optic using a technology called Q-switching. The laser’s power supply can pulse the power on and off at different frequencies (the rate at which it turns on/off). This technology and the wavelength of light (“color” or type of light) allow for the engraving or cutting of metal materials. Engraving Fiber Machines are typically less than 50 watts of power while cutting Fiber Machines now go up to 30 thousand watts of power.

- MOPA Fiber Laser: Very similar to the Fiber Laser in 1 above but its internal technology allows this machine to pulse (turn on/off) differently than the standard Fiber Laser. This gives it a unique ability to “engrave” in color on stainless steel. The MOPA laser’s wavelengths and frequencies react to the metal causing the stainless metal to turn different colors. The MOPA laser is slower than the standard Fiber laser but it has a color palette and superior ability to engrave on plastics that make the MOPA laser an attractive option.

- CO2 Laser: The CO2 Laser is an old and time-tested technology. It’s been used within the industry for more than 40 years with great success. Electrical power is sent through a vacuum-sealed tube of laser gas containing CO2. The CO2 becomes excited and releases energy in the form of laser light. The CO2 laser beam is ideal for engraving or cutting non-metal materials like wood, leather, paper, acrylics, and other organic materials. It’s the most popular laser source on the market today and is offered in large and small laser engraving and cutting machines. Higher-power CO2 Lasers are sold as metal cutting systems and offer great edge quality and flexibility. High-Power Fiber Lasers have now overcome CO2 lasers in the high-power market of 1,000W or more due to its wider variety of metals its capability of cutting and its low cost of ownership due to fewer moving parts.

- UV Laser: The UV Laser is technically called an ultraviolet diode laser, or commonly just referred to as a Diode Laser. This is an electronic device, a semiconductor device like the red or green LEDs you may see on a TV remote or garage door opener. The Diode Laser generates its laser beam through the passing of electrical energy through the diode’s solid-state internal structure. The diode used in laser engraving emits a visible laser beam and can range in power from a few milliwatts to tens of watts. This laser is best suited for organic materials such as polymers, plastics, wood, and glass. Because of its typically lower power, it is slower than the CO2 laser. However, it can create very detailed and beautiful artwork.

Table 1. A General Laser Processing Material List.

Power, Table Size, Options

Now you have an idea of the types of laser sources available you need to think of laser power, machine size, and what options? This is sometimes confusing due to all the options available and the cost differences. Here’s a simple process I hope will help you make your decision:

Power

- Low power often allows for greater detail in engraving.

- High power allows for faster speeds – both engraving and cutting speeds.

- High power increases your thickness capacity.

- Usually, 30W-50W Fiber is sufficient for most engraving.

- 60-80W CO2 is a perfect range for general laser use. Great flexibility in detail, speed, and capacity.

- 150W CO2 is great for cutting, with less detail in engraving.

Table Size

- Determine your largest part size. This will determine your best machine size.

- Decide on the floor space available. Lasers use more space around the machine than you realize. Allow for raw material and finished part storage space at the laser. If you are cutting 24” x 16” plywood you should have space next to the laser to store the plywood needed to complete the job. The same is true for parts coming off the laser. Allow space for part storage before they go to the next step of manufacturing.

- Does your table allow for thick material or large three-dimensional parts such as wooden boxes, containers, or drinkware rotary devices? The Z-Axis is the up/down portion of the laser and should be able to accommodate all your targeted products and services.

Options

- Software: Lasers are driven by software. You need to create a program that then will be sent to the laser for processing. The laser engraving and cutting process begins with an idea. This idea is then recreated in a software package, processed into laser usable program, and then cut by the laser. The design portion is often done in drawing or CAD programs such as Corel Draw, Adobe Illustrator, AutoCAD, Solidworks, or any of the numerous programs on the market. The drawing then needs to be processed through another program to convert it into something the laser machine can use to make parts. This computer-aided manufacturing (CAM) software is what controls the laser’s movement and power. Programs such as RDWorks, Lightburn, and Engrave Labs control movement and power. Programs such as RDWorks, Lightburn, EngraveLab, and LaserGRBL are popular among laser engravers. Industrial packages such as SigmaNest, ProNest, JetCAM, and Striker systems offer complete nesting and post-processing for numerous industrial systems.

- Rotary Device: Rotary work allows you to laser engrave or cut cylindrical objects such as pens, drinkware, baseball bats, rings, etc. Select the rotary device based on your current need. Doing this gives you immediate processing and service of your existing product line. Trying to predict what you may or would like to process in the future is difficult. If you like to engrave drinkware tumblers, then select a rotary device able to accommodate your current offerings. There are numerous options available for the engraving market. A simple roller-style rotary is good for drinkware, bats, and other cylindrical objects. You can get large devices for tumblers smaller ones for pens, and other smaller promotional items. A “Chuck” style is also available. Depending on the size of the device these can be used for rings, bats, drinkware, or hard-to-hold objects. The options are varied but stay focused and select something that will perform well processing your current product line!

- Assist Gas: Get a good source of assist gas source such as a dedicated air compressor. This helps in both cutting and engraving and increases the quality and consistency of the process.

- Fume Extraction: Laser engraving creates fumes. Some of these can be toxic so refer to your Material Safety Data Sheet (MSDS) to see if the material can be safely laser processed. Those non-toxic fumes can also cause problems in the shop. Headaches are often the number one issue. Vent those fumes through some sort of exhaust handler to reduce those smells. There are two main options when it comes to fume exhaust. You can vent it outside or process it through a filtration system. Talk with your laser representative for the best options for your shop.

- Material Handling: The last option mentioned is often overlooked at the startup – material handling. To properly handle materials set up the process flow so that the materials are easily accessible to the operator and easily fed into the machine. The parts produced should be in easy reach within the machine and after removal should be stored in a safe location near the machine to wait for further processing. Having proper work height feed tables reduces movement and creates a safer work environment – resulting in a better work experience.

Time to Choose

Now where was I? Ah yes, I was planning my business by asking some questions and talking to the appropriate suppliers. I was able to create a list of startup equipment and supplies that I was confident would support my initial business launch. I knew once I got the business started opportunities would arise that would allow growth in new product lines and potential. But using that simple list of goals I was able to narrow down the required equipment and supplies to start my new business.

Now 40 years later, I hope this blog post will help guide you through the laser selection process and launch you into your business! If you need help or inspiration on starting your laser business feel free to contact me.

Writer Anthony Isaac can be reached via the Contact Me page.